Porsche engines are renowned for their engineering excellence and reliability, but the IMS bearing issue has been a significant concern for owners of certain models. This problematic component has caused anxiety for many Porsche enthusiasts, potentially leading to catastrophic engine failures if left unaddressed. For those wondering which Porsche models are affected by IMS bearing issues and what solutions are available, this comprehensive guide will provide the essential information you need to protect your performance vehicle.

Porsche Models Affected by IMS Bearing Issues

The IMS (Intermediate Shaft) bearing problem affects water-cooled Porsche models manufactured between 1997 and 2008. Specifically, the following models are susceptible:

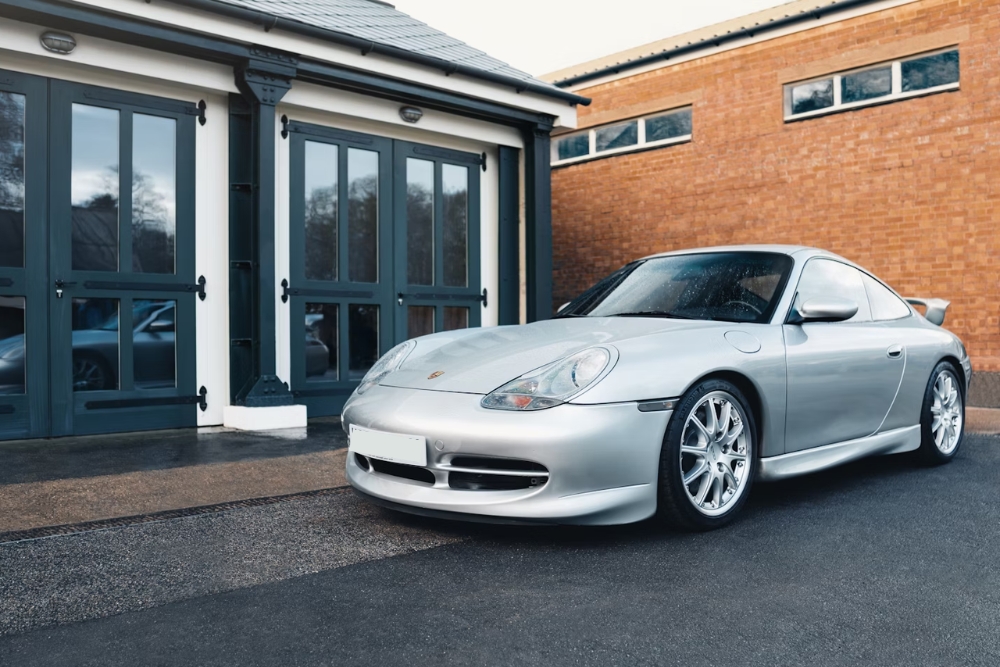

Porsche 911 (996 Generation)

All non-Turbo, non-GT variants of the 996 generation 911 produced from 1999 to 2005 come equipped with the potentially problematic M96 engines. These models utilise an intermediate shaft supported by a sealed ball bearing that can fail without warning.

Porsche 911 (997 Generation)

Early 997 generation models from 2005 to 2008 with the M97 engine can also experience IMS bearing issues. However, these later models feature a larger, more robust bearing design that somewhat reduced (but did not eliminate) the failure rate.

Porsche Boxster (986 Generation)

The first-generation Boxster models from 1997 to 2004 share the same M96 engine architecture as the 996 and therefore face similar IMS bearing concerns.

Porsche Boxster and Cayman (987 Generation)

Early 987 generation Boxsters and Caymans produced between 2005 and 2008 can also suffer from IMS bearing failure, though with the revised larger bearing design found in the contemporary 997 models.

It’s important to note that Turbo, GT2, and GT3 variants of the 911 utilise the Mezger engine design, which does not have the problematic IMS bearing configuration. Additionally, all Porsche models from 2009 onwards feature the new 9A1 engine design that completely eliminates the intermediate shaft altogether.

Understanding the Problem: Why IMS Bearings Fail

The IMS bearing failure issue centres around a fundamental design flaw. The intermediate shaft in these engines is supported by a sealed ball bearing on the flywheel end of the engine. This bearing serves a critical function—supporting the shaft that drives the camshafts through timing chains.

The primary causes of failure include:

- Inadequate lubrication: The sealed design of the original bearings prevents proper oil flow, leading to lubrication starvation and premature wear.

- Bearing type changes: Porsche used different bearing types throughout the production years, with the single-row bearing (used primarily from 2000 to 2005) being particularly prone to failure due to its reduced load capacity.

- Insufficient load rating: Many of the original bearings were not adequately rated for the loads they would experience during normal operation.

The model years 2000 to 2005 with the single-row bearing design have shown the highest failure rates, potentially reaching 8% during warranty periods according to information from the Eisen class action lawsuit against Porsche. Post-warranty failure rates are believed to be significantly higher.

Warning Signs of IMS Bearing Failure

Unfortunately, detecting IMS bearing problems before catastrophic failure is challenging. There are few reliable early warning signs, but vigilant owners should watch for:

- Metal particles in engine oil or trapped in the oil filter during service

- Unusual noises from the engine, particularly rattling sounds at startup or when accelerating

- Changes in engine timing or performance

By the time these symptoms appear, however, significant damage may have already occurred. This is why preventative action is strongly recommended for all affected models.

Effective Solutions for Porsche IMS Bearing Issues

Several solutions have been developed to address the IMS bearing problem, ranging from complete replacement to more extensive retrofits:

IMS Bearing Replacement Options

- IMS Retrofit Kit: A ceramic hybrid ball bearing replacement that offers improved durability over the original factory bearing. These typically have service intervals of 6 years or 75,000 miles.

- IMS Solution: This is considered by many specialists to be the only permanent solution to the IMS bearing problem. It replaces the problematic sealed ball bearing with an oil pressure-fed plain bearing, similar to what was used in the more reliable Mezger engines. This solution requires no service interval as it’s designed for the life of the engine.

- Roller Bearing Replacements: Some aftermarket options utilise cylindrical roller bearings with integrated thrust capabilities, offering another alternative to the factory bearing.

Best Practices for IMS Bearing Health

Even with replacement options, proper maintenance is essential:

- More frequent oil changes: Changing engine oil every 5,000 miles or 6 months helps ensure proper lubrication and can extend bearing life.

- Using appropriate oil: High-quality synthetic oils designed for performance engines are recommended over standard lubricants.

- Regular driving habits: Avoiding short trips and maintaining higher RPMs (above 2,500-3,000) when driving can help ensure proper bearing lubrication.

- Proactive replacement: For models with the accessible IMS bearing (1997-2005), replacing it as a preventative measure during clutch service (when the transmission is already removed) can save significant labour costs.

When to Address IMS Bearing Issues

The best approach to the IMS bearing issue is proactive replacement before failure occurs. For 1997-2005 models with the accessible bearing, consider replacement:

- When purchasing a used vehicle with unknown maintenance history

- During scheduled clutch replacement (saving on labour costs)

- Before the vehicle reaches 50,000-60,000 miles if no previous replacement has been performed

- If the car has been sitting unused for extended periods

For 2006-2008 models with the non-serviceable bearing, options are more limited but include removing the grease seal to allow better oil flow to the bearing.

Need Help Servicing Your Porsche?

If you own an affected Porsche model, taking action on the IMS bearing issue is not just about avoiding costly repairs—it’s about protecting your investment and ensuring continued driving enjoyment. As an independent porsche service shop based in Auckland, Dodson Motorsport offers expert assistance with IMS bearing replacements and upgrades.

For peace of mind and to ensure your Porsche’s engine remains in optimal condition, contact Dodson Motorsport today on 09 441 3635 or email service@dodsonmotorsport.com to discuss your IMS bearing replacement options. Taking preventative action now can save you from expensive engine rebuilds and keep your Porsche performing at its best for years to come.

Looking for Dual Clutch transmission components outside of New Zealand?

Looking for Dual Clutch transmission components outside of New Zealand?