When building or modifying a performance vehicle, every component plays a crucial role in ensuring optimal performance and longevity. Transmission coolers have become an increasingly important consideration for enthusiasts pushing their vehicles to the limit, yet many builders remain uncertain about whether their specific project requires one. This article explores the essential role of transmission coolers, when they become necessary, and how to determine if your build would benefit from this critical cooling component.

When Transmission Coolers Become Essential for Your Build

The need for a transmission cooler largely depends on how you plan to use your vehicle and the demands you’ll place on the transmission system. For daily drivers that occasionally see spirited driving, the factory cooling system might suffice. However, once you start adding power modifications, engaging in track days, or towing heavy loads, the heat generated by your transmission can quickly exceed the capacity of standard cooling systems.

Performance driving generates significant heat through the transmission fluid, and temperatures above 90°C can start breaking down the fluid’s protective properties. Track sessions, repeated hard launches, and sustained high-speed driving all contribute to elevated transmission temperatures. In Auckland’s varied climate, from cool winters to warm summers, these temperature fluctuations can further stress your transmission system, making auxiliary cooling even more beneficial.

Modified vehicles with increased horsepower and torque place substantially more stress on transmission components. Whether you’ve upgraded your turbo system, installed a supercharger, or built a naturally aspirated engine with higher compression, the additional power translates directly to increased heat generation within the transmission. This heat buildup accelerates wear on clutch packs, bearings, and seals, potentially leading to premature failure without adequate cooling.

Types of Transmission Coolers for Different Applications

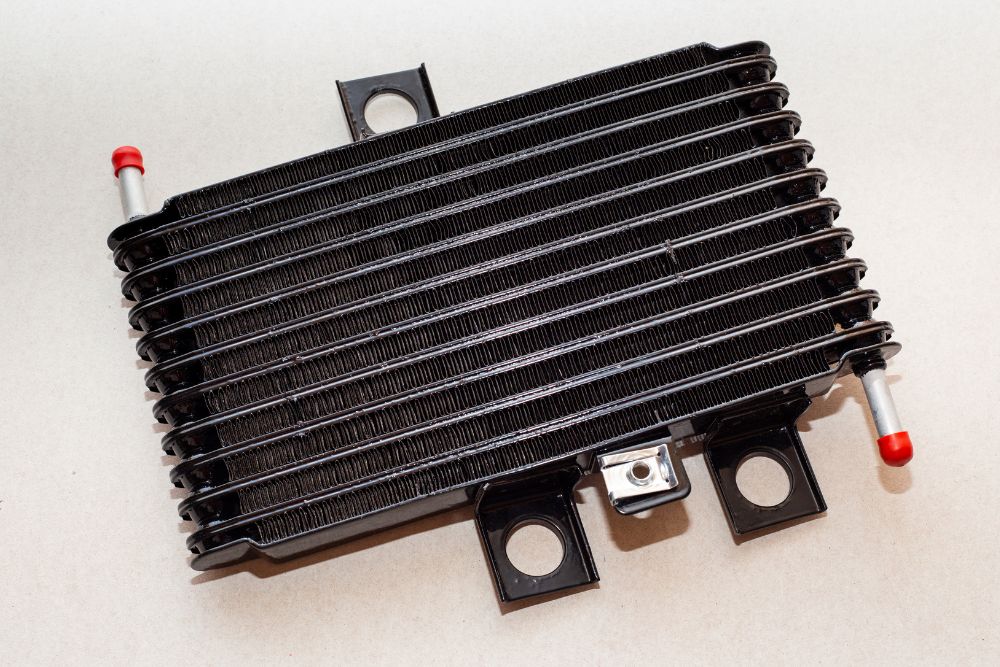

Selecting the right transmission cooler involves understanding the various types available and matching them to your specific requirements. Tube-and-fin coolers represent the most common and cost-effective option, offering good cooling capacity for street-driven vehicles with mild modifications. These coolers work well for cars that see occasional spirited driving or light track use, providing a noticeable improvement over factory cooling systems.

Plate-and-fin coolers offer superior cooling efficiency compared to tube-and-fin designs, making them ideal for more demanding applications. The increased surface area and improved heat dissipation characteristics make these coolers perfect for heavily modified street cars, weekend warriors, and vehicles that regularly participate in track events. The compact design also allows for easier installation in tight spaces, which can be crucial in modern performance vehicles.

Stacked-plate coolers represent the pinnacle of transmission cooling technology, providing maximum heat dissipation for extreme applications. These coolers excel in dedicated race cars, heavily modified street vehicles producing significant power, and cars subjected to extended periods of high-stress driving. While more expensive than other options, the investment pays dividends in transmission longevity and consistent performance under demanding conditions.

Installation Considerations and Placement Strategies

Proper installation and placement of your transmission cooler significantly impacts its effectiveness. The cooler needs adequate airflow to function optimally, which means positioning it in the direct path of incoming air. Common mounting locations include in front of the radiator, beside the radiator, or in dedicated cooling ducts. Each location offers advantages and disadvantages that must be weighed against your specific vehicle configuration and cooling requirements.

Mounting the cooler in front of the radiator provides excellent airflow but can reduce engine cooling efficiency. This trade-off works well for vehicles with robust engine cooling systems but might prove problematic for cars already running near their cooling limits. Side-mounting positions offer a good compromise, providing adequate airflow without impeding radiator performance, though they may require custom brackets and careful routing of cooling lines.

The size and routing of transmission cooling lines play a crucial role in system effectiveness. Using appropriately sized lines ensures adequate flow rates while minimising pressure drops that could affect transmission operation. Quality fittings and proper line routing prevent leaks and ensure long-term reliability. Consider using braided stainless steel lines for their durability and resistance to heat and abrasion, particularly in high-performance applications.

Benefits Beyond Temperature Control

While temperature management remains the primary function of transmission coolers, they provide several additional benefits that enhance overall vehicle performance and reliability. Consistent transmission temperatures lead to more predictable shift characteristics, particularly important in performance driving situations where precise gear changes can make the difference between a fast lap time and mechanical failure.

Extended fluid life represents another significant advantage of auxiliary transmission cooling. By maintaining optimal operating temperatures, the transmission fluid retains its protective properties longer, reducing the frequency of expensive fluid changes. This becomes particularly important with high-performance synthetic fluids, which can cost several hundred dollars per change. The cooler essentially pays for itself through reduced maintenance costs over time.

Improved transmission longevity directly results from better temperature management. Heat remains the primary enemy of automatic and dual-clutch transmissions, accelerating wear on friction materials and degrading seals. By maintaining temperatures within the optimal range, transmission coolers can double or even triple the service life of internal components, delaying the need for expensive rebuilds or replacements.

Determining Your Specific Cooling Requirements

Assessing your actual cooling needs requires honest evaluation of your driving habits and vehicle modifications. Weekend cruisers with mild modifications might find that a small tube-and-fin cooler provides adequate protection, while dedicated track cars demand more robust solutions. Consider factors such as ambient temperatures in your area, the duration of high-stress driving sessions, and the power levels your vehicle produces.

Data logging provides invaluable insights into your transmission’s thermal behaviour. Installing a temperature gauge or using diagnostic tools to monitor transmission temperatures during various driving conditions reveals whether your current cooling system suffices. Temperatures consistently exceeding 100°C indicate an immediate need for auxiliary cooling, while readings between 90-100°C suggest that a cooler would provide beneficial added protection.

Future modification plans should factor into your cooling system decisions. If you intend to increase power levels, add forced induction, or participate in more demanding driving events, installing a transmission cooler now prevents potential damage down the road. Choosing a cooler with capacity beyond your current needs provides headroom for future upgrades without requiring system replacement.

Common Misconceptions About Transmission Cooling

Several myths persist regarding transmission coolers that can lead to poor decisions or unnecessary expenses. The belief that coolers only benefit automatic transmissions overlooks the significant heat generated by modern dual-clutch and even manual transmissions under hard use. High-performance manual transmissions with upgraded clutches and close-ratio gearing can benefit substantially from auxiliary cooling, particularly in track applications.

Another misconception suggests that bigger always equals better when selecting a cooler. Oversized coolers can actually prove detrimental in street applications, preventing the transmission from reaching optimal operating temperature during normal driving. This leads to increased wear, poor shift quality, and reduced fuel efficiency. Matching cooler capacity to actual requirements ensures optimal performance across all driving conditions.

The idea that factory cooling suffices for all applications ignores the conservative nature of OEM designs. Manufacturers design cooling systems for average use cases, not the extremes encountered in performance driving. Even unmodified performance cars can benefit from auxiliary cooling when subjected to track days or aggressive driving, as factory systems often struggle to maintain safe temperatures under these conditions.

Integration with Other Cooling Systems

Successful transmission cooler installation requires consideration of the entire vehicle cooling system. Adding a transmission cooler affects airflow to other heat exchangers, potentially impacting engine oil coolers, intercoolers, and radiators. Planning the complete cooling package ensures each component receives adequate airflow without compromising the others.

Thermostatically controlled systems offer the best of both worlds, allowing rapid warm-up while providing maximum cooling when needed. These systems use a thermostat to bypass the cooler until the transmission reaches operating temperature, then progressively direct more flow through the cooler as temperatures rise. This approach works particularly well for street-driven vehicles that see occasional track use.

Electric fans can significantly improve cooler efficiency, particularly in stop-and-go traffic or during pit stops at track events. Mounting a slim electric fan behind the transmission cooler ensures consistent airflow regardless of vehicle speed. Thermostatic switches automate fan operation, activating cooling only when needed to minimise electrical draw and noise.

Need Help With Transmission Cooling for Your Build?

Determining the right transmission cooling solution requires expertise in both thermal management and transmission systems. At Dodson, we specialise in high-performance transmission services and can help you select and install the perfect cooling system for your specific build. Contact our team today by calling 09 441 3635 to discuss your transmission cooling needs and ensure your performance vehicle operates at its best.

Looking for Dual Clutch transmission components outside of New Zealand?

Looking for Dual Clutch transmission components outside of New Zealand?